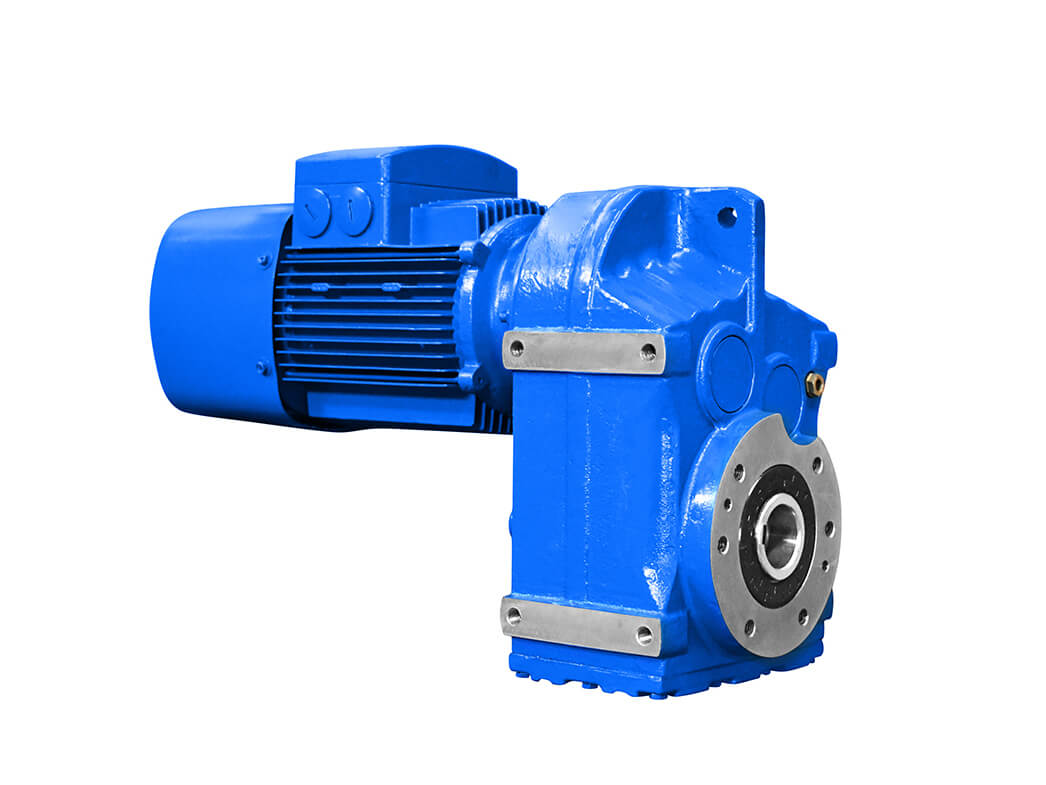

The R Series helical gear motor is a drive device that combines helical gear transmission technology with a motor. It utilizes a coaxial output and boasts a very compact structure. Its core design philosophy is serialization and modularization, which makes this series of products highly adaptable and can be adapted to various operating conditions through different motor combinations, mounting locations, and structural solutions.

R Series Helical Gear Motors

Description

The R Series helical gear motor is a drive device that combines helical gear transmission technology with a motor. It utilizes a coaxial output and boasts a very compact structure. Its core design philosophy is serialization and modularization, which makes this series of products highly adaptable and can be adapted to various operating conditions through different motor combinations, mounting locations, and structural solutions.

Technical Features

High Performance: This type of gear motor typically features low vibration and noise, with no-load noise controlled to ≤68dB(A) (measured at a distance of 1 meter). It also offers low energy consumption and high transmission efficiency, with a second-stage transmission efficiency of up to 96% and a third-stage transmission efficiency of approximately 94%, resulting in lower energy consumption than traditional soft-toothed gear reducers.

Rugged and Durable Design: Modular production reduces costs. The housing is cast in an integrated machining center to ensure precision. The gears are made of high-quality low-carbon alloy steel and carburized and ground, ensuring low noise, long-lasting operation, a wide speed ratio range, and compatibility.

Wide Parameter Range: The power range is extensive, from approximately 0.12 kW to 160 kW. The output torque range is also wide, from 1.4 N·m to 43,200 N·m. A wide speed ratio range is available, with basic ratios ranging from approximately 3.33 to 289.74. Through combination, the maximum transmission ratio can even reach over 2700:1.

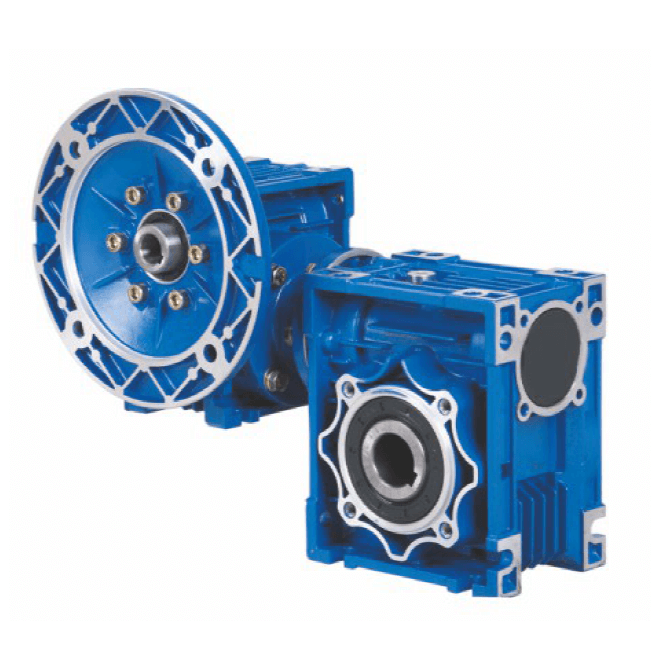

Flexible Installation: A variety of mounting options are supported, including foot-mount, flange-mount, vertical, and horizontal, allowing users to choose the right installation based on their space and structural requirements.

Main Applications

R series helical gear reducers are widely used, covering nearly all industrial sectors, such as:

Heavy Industry: Metallurgy, Mining, Hoisting and Transportation.

Light Industry and Chemical Industry: Food Processing, Beer and Beverage, Chemical Industry, Papermaking.

Environmental Protection and Infrastructure: Wastewater Treatment, Construction and Building Materials Machinery.

Automation Equipment: Automated Warehousing Equipment, Escalators. Special Occasions: They are even used in stage scenery machinery.

Selection Tips and Model Numbers

A complete model number typically includes detailed information such as the series code, frame size, motor information, gear ratio, and mounting configuration. Model example: Taking "R77-Y-0.25-4P-121.42-M1-90°" as an example:

R77: R series, frame size 77

Y-0.25-4P: Matching motor information (motor type, power, number of poles)

121.42: Gear ratio

M1: Mounting configuration

90°: Terminal box location