The S Series Gear Motors combine helical gears with worm gear transmissions. This combination inherits the advantages of a worm gear transmission's high speed ratio and self-locking function while achieving higher transmission efficiency and load capacity. This series utilizes a fully modular design, resulting in a compact design and small footprint.

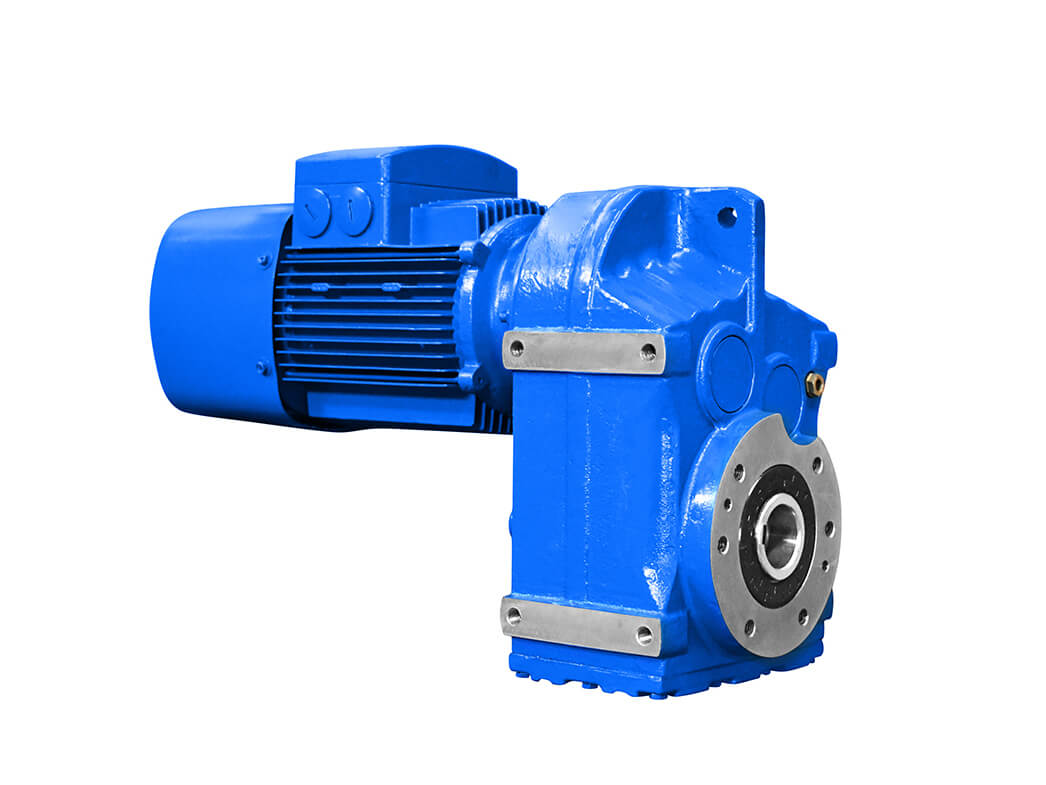

S Series Gear Motors

Description

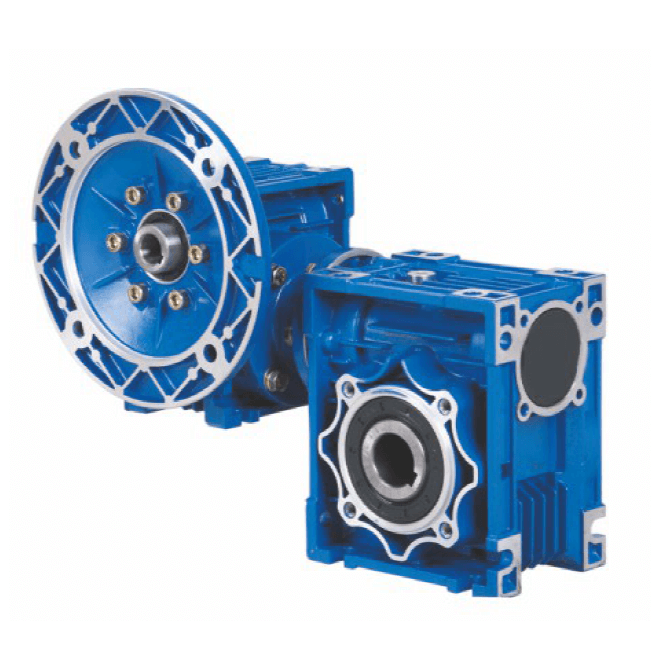

The S Series Gear Motors combine helical gears with worm gear transmissions. This combination inherits the advantages of a worm gear transmission's high speed ratio and self-locking function while achieving higher transmission efficiency and load capacity. This series utilizes a fully modular design, resulting in a compact design and small footprint. It also offers easy assembly and versatility, allowing for flexible adaptation to various installation methods and power requirements.

Technical Features

Efficient Transmission and Powerful Torque: The helical gear and worm gear combination delivers improved torque and efficiency. A wide range of speed ratios is available, with basic models ranging from 9.96–244.74. Some models can even achieve extremely high speed ratios (such as 8608) or achieve extremely low output speeds. Furthermore, this series delivers output torques of up to 3800 Nm and higher, and can withstand high radial loads, with some models capable of withstanding radial loads up to 30,000 N.

Stable, Reliable, and Durable: Key components of the S-series reducer motors are typically made of high-quality alloy steel and undergo heat treatment processes such as carburizing and quenching. This results in high tooth surface hardness and excellent wear resistance, ensuring product reliability and long life. Gears are ground with high precision, ensuring smooth transmission. The housing is mostly constructed of high-strength cast iron, with an optimized design, offering high mechanical strength and excellent heat dissipation.

Flexible Installation and Wide Application: This series offers a variety of mounting options, including foot mounting, flange mounting, and hollow shaft mounting, to accommodate complex installation spaces. Its excellent sealing performance makes it highly adaptable to working environments. Furthermore, the S-series reducer can be configured with a variety of motors, including conventional motors, explosion-proof motors, and brake motors, achieving mechatronic integration.

Main Applications

Due to its compact structure, large speed ratio, and high efficiency, the S-series reducer motor is widely used in machinery and equipment across a wide range of industries, including:

Conveying and lifting equipment: such as conveyor belts, elevators, and multi-story parking garages.

Industrial Production: Powering equipment such as mixers and assembly lines in the food, chemical, textile, packaging, pharmaceutical, and environmental protection industries.

Heavy Machinery: Also commonly used in heavy industries such as steel smelting, crane construction, petrochemicals, and mining.

Selection Tips and Model Numbers

Model Number Example: Taking "SA67-Y2.2-62.35" as an example:

S: Represents an S-series helical-worm gear reducer.

A: Represents the hollow shaft mounting configuration.

67: The frame size.

Y: Represents the matching three-phase AC asynchronous motor.

2.2: Represents a 2.2kW motor power.

62.35: Represents the transmission ratio.

Other common mounting designations include SF (shaft-mounted flange) and SAF (shaft-mounted flange).

Important Considerations: When selecting a suitable model, consider factors such as the required output torque, output speed, operating environment, and installation space limitations.