Product DescriptionThe two-stage worm gear reducers are engineered by combining two single-stage units in series. This robust design inherits all the advantages of the single-stage reducer while achieving significantly larger transmission ratios.Key Features & Benefits:Massive Speed Reduction: P

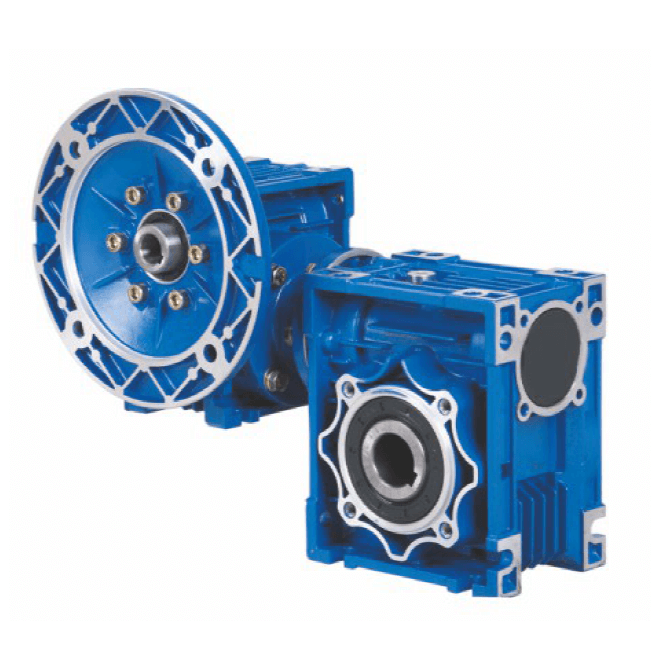

Double-Stage Worm Gearbox

Product Description

The two-stage worm gear reducers are engineered by combining two single-stage units in series. This robust design inherits all the advantages of the single-stage reducer while achieving significantly larger transmission ratios.

Key Features & Benefits:

Massive Speed Reduction: Perfect for applications requiring very low output speeds and high torque.

Compact & Modular Design: Built from proven NMRV/NRV components, ensuring reliability and a space-saving footprint.

Smooth & Quiet Operation: Maintains the low noise and vibration characteristics of the single-stage series.

High Torque Output: Capable of transmitting substantial torque for demanding industrial tasks.

Standard Combination Models:

We offer a range of standard two-stage combinations to meet various power and ratio requirements. The model numbers represent the frame sizes of the combined units. 25/30, 25/40, 30/40, 30/50, 30/63, 40/75, 40/90, 50/110, 63/130, 63/150

Custom Combinations Available

Can't find the perfect match? We provide flexible custom solutions. You can select from our standard single-stage units as building blocks to create your ideal two-stage reducer. Available frame sizes for custom combinations include:

25, 30, 40, 50, 63, 75, 90, 110, 130, 150

This modular approach allows you to tailor the performance and mounting configuration to your specific application needs.

Model Notes

NMRV-063/130-600-VS-F1(FA)-AS-80B5-0.75kW-AS1 | |

NMRV-NMRV | Combined worm gear speed reducer |

NRV-NMRV | Worm gear speed reducer (matching input shaft) |

063/130 | Center distance |

600 | Reduction ratio |

VS | Double input shaft |

F1(FA) | Output flange |

AS | Single output shaft |

AB | Double output shaft |

PAM | Fitted for motor coupling |

80B5 | Motor mounting facility |

0.75kW | Electric motor power |

As1 | Mounting position |