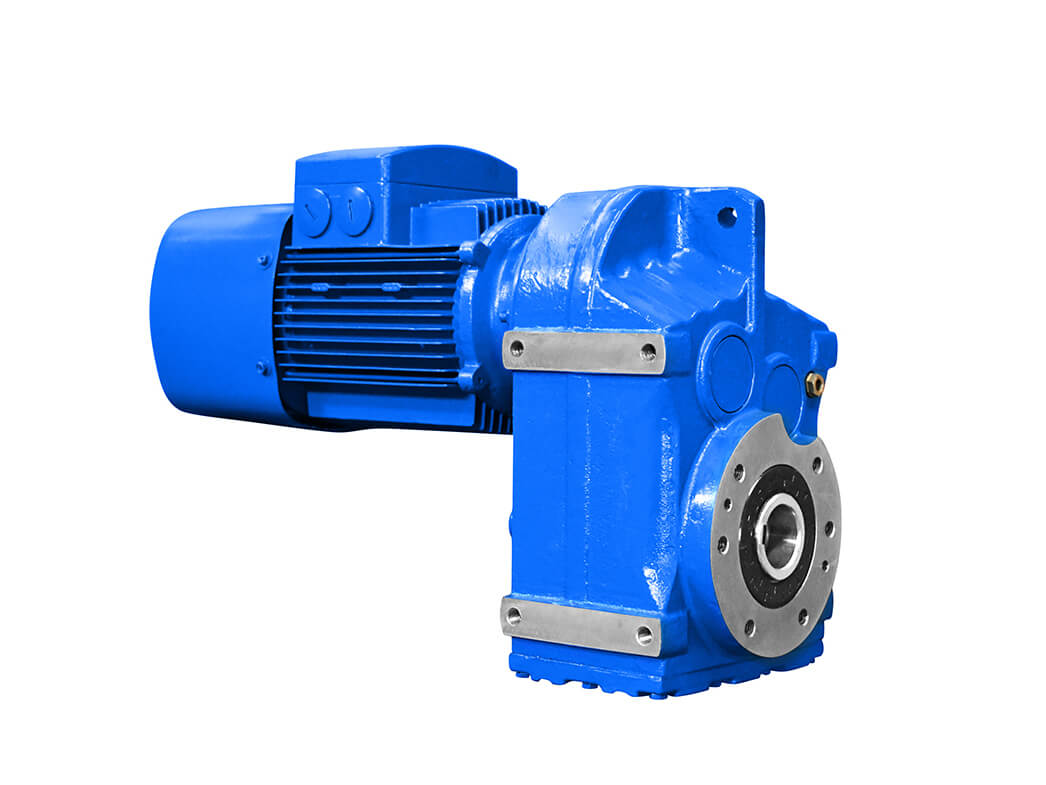

The K series gear motor is a spiral bevel gear (or bevel gear) reducer, renowned for its right-angle output design. It features an integrated motor and reducer design, utilizing a combination of helical and spiral bevel gears for power transmission. It is particularly suitable for industrial equipment requiring variable direction of motion.

K Series Bevel Gear Motors

Description

The K series gear motor is a spiral bevel gear (or bevel gear) reducer, renowned for its right-angle output design. It features an integrated motor and reducer design, utilizing a combination of helical and spiral bevel gears for power transmission. It is particularly suitable for industrial equipment requiring variable direction of motion.

Technical Features

The K series gear motors are popular across numerous industrial sectors due to their multiple advantages in design, materials, and performance.

High Transmission Efficiency: Utilizing hardened gears and an optimized transmission structure, the K series achieves an average transmission efficiency exceeding 94%, with some models exceeding 95%, helping to reduce operating energy consumption.

Compact Structure and Right-Angle Output: Using spiral bevel gears for right-angle transmission, this design effectively saves installation space and is particularly suitable for compact equipment.

High Torque and Strong Load-bearing Capacity: Gears are made of high-quality alloy steel (such as 20CrMnTi) and undergo heat treatment processes such as carburizing and quenching. The gear surfaces are highly hard (up to HRC58-62) and wear-resistant, capable of withstanding heavy radial and axial loads. Output torque reaches up to 50,000 Nm.

Modular Design: The modular design offers excellent adaptability and allows for flexible integration with various motor types (such as three-phase asynchronous motors, variable-frequency motors, and servo motors). It supports a variety of mounting methods, significantly reducing component variety and inventory requirements.

Smooth Operation and Long Life: Gears are precision-ground (to a precision of 5-6) for smooth transmission. Combined with a rigid cast iron housing (some smaller sizes are aluminum) and a well-sealed structure, the product offers low vibration, low noise, minimal maintenance, and a long service life.

General Technical Parameters

Parameter Parameter Range

Motor Power 0.18 kW to 200 kW

Output Torque Up to 50,000 Nm

Output Speed 0.08 to 263 rpm

Gear Ratio Finely graduated, wide range (e.g., 8 to 200)

Mounting Methods Foot mount, flange mount (KF), hollow shaft mount (KA), etc.

Typical Efficiency > 94%

Main Applications

Due to their excellent performance, K series geared motors are widely used in the following industries and equipment:

Lifting and Transportation: Cranes, conveyor belts, and hoisting equipment.

Heavy Machinery: Mining machinery, metallurgical equipment, and building materials equipment.

Chemical and Environmental Protection: Mixers, mixing equipment, and environmental protection machinery.

General Industry: Food machinery, packaging machinery, pharmaceutical equipment, and stage machinery.

Selection Tips and Model Numbers

Model Example: Taking "KF97-Y1.5-176.05" as an example:

K: Represents the K series helical-bevel gear reducer.

F: Represents the flange mounting method (other common mounting method codes include foot mounting (K) and hollow shaft mounting (KA).

97: Represents the frame size; a larger number generally indicates a greater torque capacity.

Y1.5: Matches the Y series three-phase asynchronous motor with a power of 1.5 kW.

176.05: Represents the gear ratio.