The TQ-4D is a high-performance, fully automatic terminal cross-section analyzer designed for quality control in the wire harness industry. It integrates precision cutting, grinding, etching, imaging, and intelligent analysis into one seamless process, enabling fast and accurate end-to-end analysis of terminal samples up to 150mm² (optional) for both low and high-voltage applications.

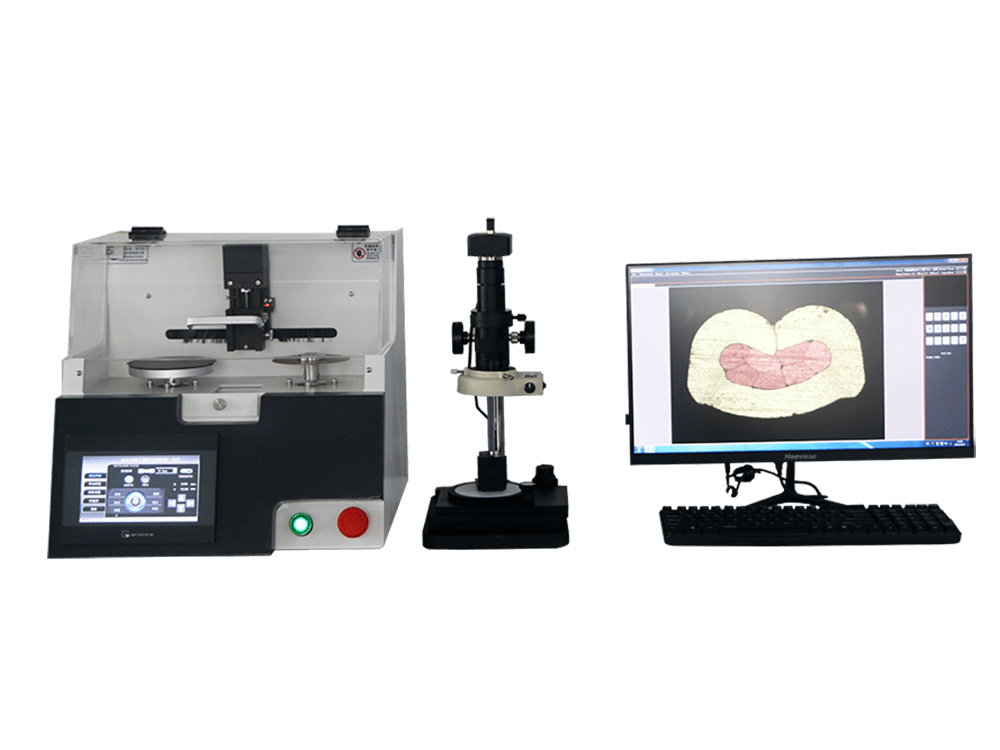

TQ-4D Fully Automatic Terminal Cross-Section Analyzer

Product Overview

The TQ-4D is a high-performance, fully automatic terminal cross-section analyzer designed for quality control in the wire harness industry. It integrates precision cutting, grinding, etching, imaging, and intelligent analysis into one seamless process, enabling fast and accurate end-to-end analysis of terminal samples up to 150mm² (optional) for both low and high-voltage applications. With optional air cooling and dust extraction systems, it ensures clean and convenient operation, making it an ideal solution for wire harness inspection in sectors such as home appliances, automotive, electrical, IT peripherals, and rail transportation.

Key Features

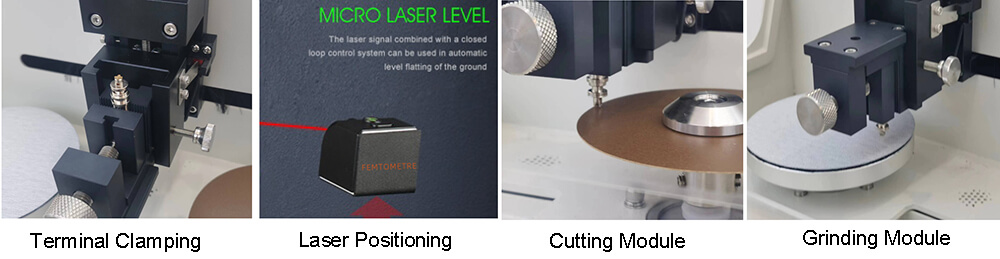

Fully Automated One-Touch Operation: Automates the entire workflow from sample clamping to final report generation, significantly improving inspection efficiency and consistency.

Intelligent Analysis Software: Equipped with Smart Vision intelligent scanning analysis software, capable of automatically measuring dozens of key parameters including C/H, C/W, wall thickness, burrs, compression ratio, and void ratio, meeting stringent automotive and electronics industry standards.

Modular Precision Sample Preparation: Features independent, automated cutting, grinding, and etching modules to ensure the preparation of high-quality, deformation-free observation surfaces.

High-Definition Extended Depth of Field Imaging: Incorporates a 5-megapixel industrial camera and an Extended Depth of Field (EDOF) optical system, providing clear magnified images from 45X to 512X for exceptional detail observation.

Clean & Eco-Friendly Options: Optional air cooling and dust extraction systems effectively manage heat and dust generated during sample preparation, maintaining a clean laboratory environment.

TECHNICAL SPECIFICATIONS

Module | Specification |

Analysis Range | Cross-Section Area: 0.01mm² – 90mm² (Standard), Up to 150mm² (Optional) |

Precision Cutting Module | Cutting Range: φ0.01mm – φ10mm; Speed: 2800 rpm |

Precision Grinding Module | Speed: 2800 rpm; Z-axis Fine Adjustment: 0-15mm; Sandpaper: 2500# |

Etching Module | Method: Dedicated chemical cleaning (3-5 sec); Electrolytic etching (Optional) |

Optical Imaging Module | System: EDOF Optical; Magnification: 45X – 512X; Camera: 5 Megapixels |

Software Analysis Module | Smart Vision Intelligent Software, fully automatic analysis of C/H, wall thickness, burrs, compression ratio, void ratio, etc. |

Reference Scale | Accuracy: 0.01/10mm |

Power & Dimensions | Power: 110-220V AC; Dimensions: L435×W480×H430mm; Weight: Approx. 40Kg |