The TQ-3D is a semi-automatic precision inspection system specifically developed for quality control in the wire harness industry. Featuring a patented integrated cutting and grinding design, it consolidates precision sectioning, grinding, etching, high-definition imaging, and intelligent analysis into a compact unit.

TQ-3D Semi-Automatic Integrated Cutting & Grinding Terminal Cross-Section Analyzer

Product Overview

The TQ-3D is a semi-automatic precision inspection system specifically developed for quality control in the wire harness industry. Featuring a patented integrated cutting and grinding design, it consolidates precision sectioning, grinding, etching, high-definition imaging, and intelligent analysis into a compact unit. It can complete the entire process from sample preparation to analysis for a single terminal (up to 120mm²) in approximately 5 minutes. With user-friendly operation, Japanese optical components, and professional analysis software capable of automatic pass/fail judgment,it is an ideal tool for enhancing quality control efficiency on the production line.

Key Features

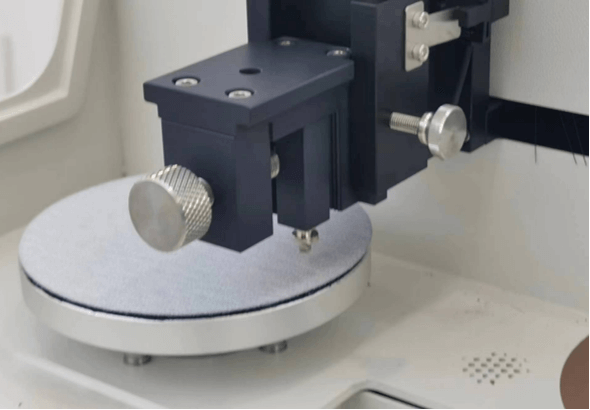

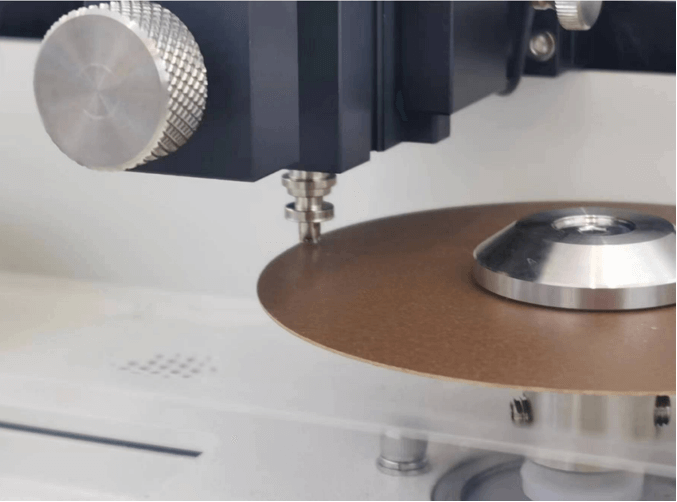

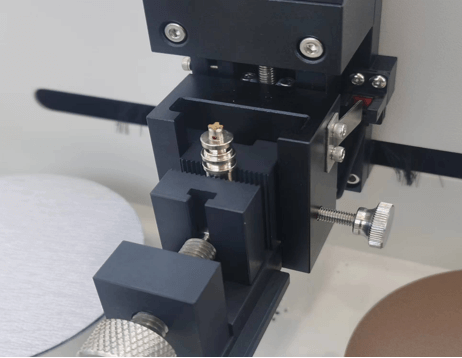

Integrated & Efficient Sample Prep: Utilizes a patented integrated cutting and grinding device to perform sectioning and grinding in one step, guaranteeing perfectly flat cross-sections and eliminating transfer errors.

Intelligent Analysis & Judgment: Built-in professional software automatically measures dozens of parameters including crimp height/width/radius, wall thickness, burrs, compression ratio, void ratio, wire count etc. and automatically calculates results against international standards to provide a pass/fail judgment, exporting a comprehensive Word report with data and cross-section images.

High-Definition Optical Imaging: Equipped with a 12-megapixel industrial camera and an Extended Depth of Field (EDOF) optical system, delivering clear magnified images from 45X to 512X for precise measurement.

Broad Compatibility & Coverage: Includes dedicated fixtures for various terminal sizes. The analysis range covers 0.01mm² to 120mm², meeting the inspection needs of wire harnesses across industries including home appliances, automotive, electrical, IT peripherals and rail transportation.

Technical Specifications

Module | Specification |

Analysis Range | 0.01mm² ~ 120mm² (Corresponding Diameter: φ0.1mm ~φ13mm) |

Precision Cutting Module | Speed: 0-5000 rpm; Cutting Wheel: ID 25.4mm, OD 110mm, Thickness 0.55mm |

Precision Grinding Module | Speed: 0-5000 rpm; Z-axis Adjustment: 0-10mm; AA-Sandpaper: 2500# |

Etching Module | Method: Dedicated chemical cleaning (3-5 sec); Electrolytic etching (Optional) |

Optical Imaging Module | System: EDOF Optical; Magnification: 45X – 512X; Camera: 12 Megapixels |

Software Analysis Module | Auto-analysis of C/H, C/W, C/R, wall thickness, burrs, compression ratio, void ratio, wire count etc. with auto judgment. |

Power & Dimensions | Power: 110-220V AC; Dimensions: L500×W350×H350mm; Weight: Approx. 30Kg |