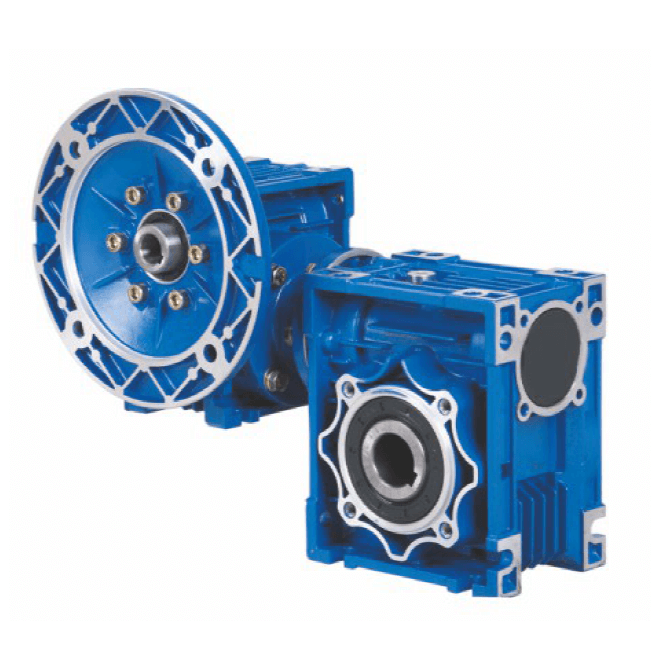

This series of industrial machinery reducer gears is designed to withstand harsh industrial environments. Made from high-quality alloy steel and advanced heat treatment processes, they offer exceptional load capacity, wear resistance, and long service life. With a wide module range, these gears meet various power transmission needs, from light-duty to heavy-duty machinery.

Industrial Machinery Reducer Gears

Product Overview

This series of industrial machinery reducer gears is designed to withstand harsh industrial environments. Made from high-quality alloy steel and advanced heat treatment processes, they offer exceptional load capacity, wear resistance, and long service life. With a wide module range, these gears meet various power transmission needs, from light-duty to heavy-duty machinery.

Core Product Advantages

Robust and Durable: Materials such as 40Cr and 20CrMnTiH are used, combined with processes like through carburizing quenching or tooth surface induction hardening, ensuring high surface hardness, excellent core toughness, and strong impact resistance.

Precision and Stability: Tooth surfaces are precision-ground to achieve JIS N7 accuracy, enabling smooth transmission, low vibration, and reduced noise, effectively enhancing overall operational stability.

Wide Compatibility: The module range of 0.8 to 20 makes these gears suitable for various industrial reducers, providing reliable solutions for heavy-duty mining, hoisting and transportation, building materials, metallurgy, and other fields.

Technical Specifications

Item | Details |

Module Range | 0.8 - 20 |

Core Material | 40Cr, 20CrMnTiH, 20Cr |

Heat Treatment | Through Carburizing Quenching / Tempering / Tooth Surface Induction Hardening |

Tooth Finishing | Precision Grinding |

Gear Accuracy | JIS N7 Grade or higher |