The New Energy E-Drive Gear Set is a core precision component within the electric vehicle drive system, specifically designed to replace traditional internal combustion engine transmissions. It efficiently and reliably converts the high-speed, low-torque output of the drive motor into the low-speed, high-torque output ideal for wheel driving through the use of high-precision meshing gears. It is a key element in achieving both powerful performance and extended range in electric vehicles.

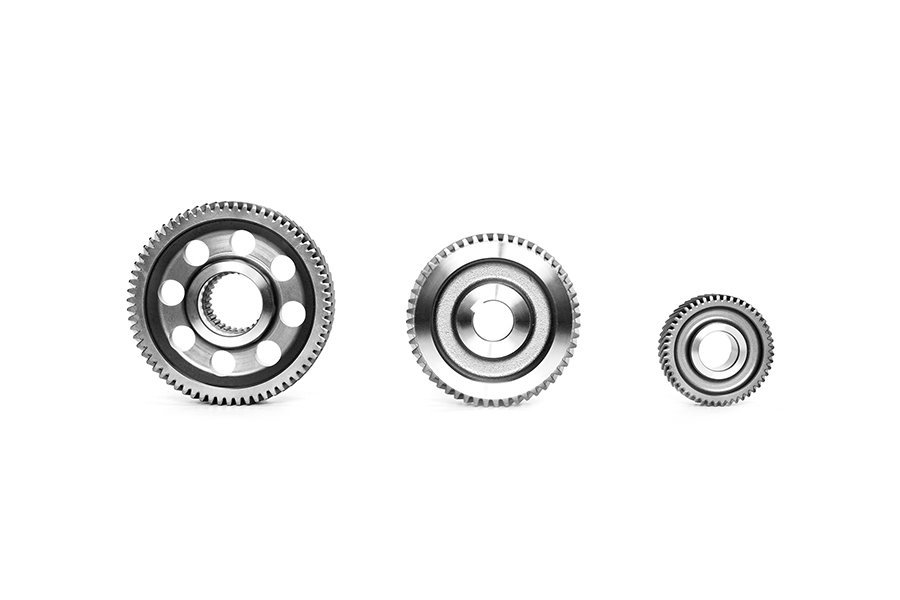

New Energy E-Drive Gear Set

Product Overview

The New Energy E-Drive Gear Set is a core precision component within the electric vehicle drive system, specifically designed to replace traditional internal combustion engine transmissions. It efficiently and reliably converts the high-speed, low-torque output of the drive motor into the low-speed, high-torque output ideal for wheel driving through the use of high-precision meshing gears. It is a key element in achieving both powerful performance and extended range in electric vehicles.

Core Technology: Why Choose Engagement Drive?

In the field of electric vehicles, engagement drive (specifically fixed-axis gear drive) is the absolute mainstream technical solution for the following reasons:

Extremely High Transmission Efficiency: The mechanical efficiency of gear meshing can reach over 98%, minimizing power loss and directly translating electrical energy into driving range.

Precise and Constant Gear Ratio: Ensures smooth and controllable power output, providing a direct driving feel that matches the motor's operational characteristics perfectly.

Compact Structure & High Power Density: Capable of transmitting significant power within a very confined space, ideally suited for the compact layout requirements of electric vehicle drive axles.

High Reliability & Long Service Life: With proper lubrication and maintenance, the service life of the gear set far exceeds the vehicle's design life.

Features of Our Gear Set Products

Our e-drive gear sets are designed and manufactured in strict accordance with the highest industry standards:

Premium Materials: Utilization of high-grade low-carbon alloy steels such as 20CrMnTiH and 40Cr, ensuring the gears possess both high surface hardness and core toughness to withstand high-frequency impact loads.

Advanced Heat Treatment: Application of through carburizing and quenching processes creates an ideal "hard exterior and a tough core" structure. This results in an extremely wear-resistant gear surface while maintaining the ability to absorb impact energy and prevent brittle fracture.

Precision Manufacturing: Gear teeth are precision ground to consistently achieve JIS N7 grade or higher accuracy. This ensures smooth meshing, fundamentally reducing operational noise and vibration, and enhancing ride comfort.

Exceptional Performance: The final product offers excellent precision, superior strength, and unparalleled wear resistance, fully meeting the stringent demands of e-drive systems for high speed, high torque, and long service life.

Typical Applications

l Pure Electric Vehicle Single-Speed Reduction Gearbox / Transmission

l Electric Drive Unit (EDU)

l Transmission systems for Hybrid Electric Vehicles (HEV/PHEV)