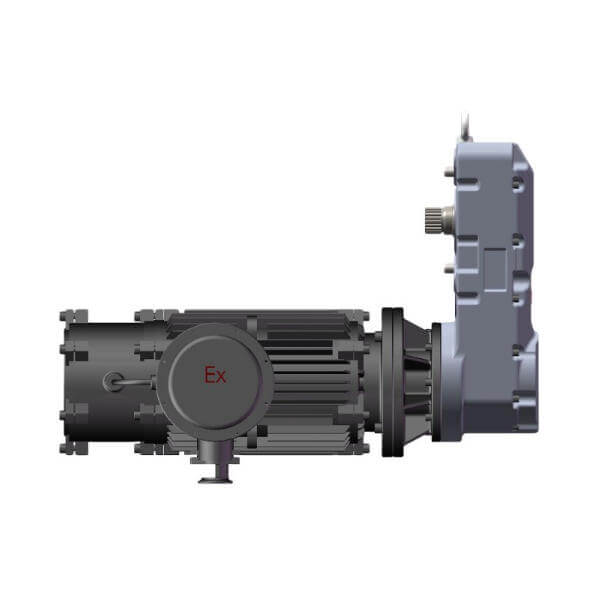

The DTQ series is an all-in-one, European-style crane hoist gearbox that meets high-end international standards. It is a high-performance, lightweight, and modular product designed for specific markets and applications.

DTQ Series Crane Hoist Gearbox

Description

The DTQ series is an all-in-one, European-style crane hoist gearbox that meets high-end international standards. It is a high-performance, lightweight, and modular product designed for specific markets and applications.

The DTQ series is a high-performance European-style crane hoist gearbox. Designed in accordance with European FEM standards, its core components utilize carburized and ground hardened gears, ensuring low noise and exceptionally long life. Its greatest advantages lie in its integration and interchangeability—the gearbox, motor, and brake are integrated into a lightweight aluminum alloy housing, providing a one-stop solution. Its mounting dimensions are fully compatible with major international brands, allowing for direct replacement, saving significant time and costs.

Product Features

1. Product Type and Market Positioning

Type: European-style hoist/crane hoist gearbox.

Design Standard: Based on the standards of the European Mechanical Handling Association (FEM).

2. Core Structure and Features

Case Material and Craftsmanship: Made of A356 aluminum alloy with a T6 heat treatment.

Advantages: Significantly reduces overall weight. The T6 treatment (solution heating followed by artificial aging) ensures the aluminum alloy housing possesses sufficient strength and hardness to meet the rigorous demands of lifting applications.

Transmission Type: Three-stage parallel shaft gear reduction.

Advantages: High transmission efficiency and compact structure. The parallel shaft design is a typical feature of hardened gear reducers, characterized by mature technology and excellent reliability.

Integrated Design: Integrated with the motor and brake.

Advantages: This is a "plug-and-play" power system solution. This eliminates the need for individual selection, assembly, and commissioning, reduces external connections, and improves system reliability and consistency.

3. Core Technology and Performance

Gear Technology: Utilizes low-carbon alloy steel and a top-tier manufacturing process using carburized and ground gears. Carburizing results in an extremely hard surface (wear resistance) and a tough core (impact resistance). The grinding process ensures extremely high tooth profile accuracy.

Reduced noise and increased lifespan. Smooth operation, low noise, high load capacity, and extremely long service life.

Interchangeability: The mounting interface is consistent with similar international products, ensuring high interchangeability. It can serve as a direct replacement for similar products from renowned international brands. Customers can seamlessly replace it during equipment maintenance or new project design, eliminating the need for retrofitting risks.