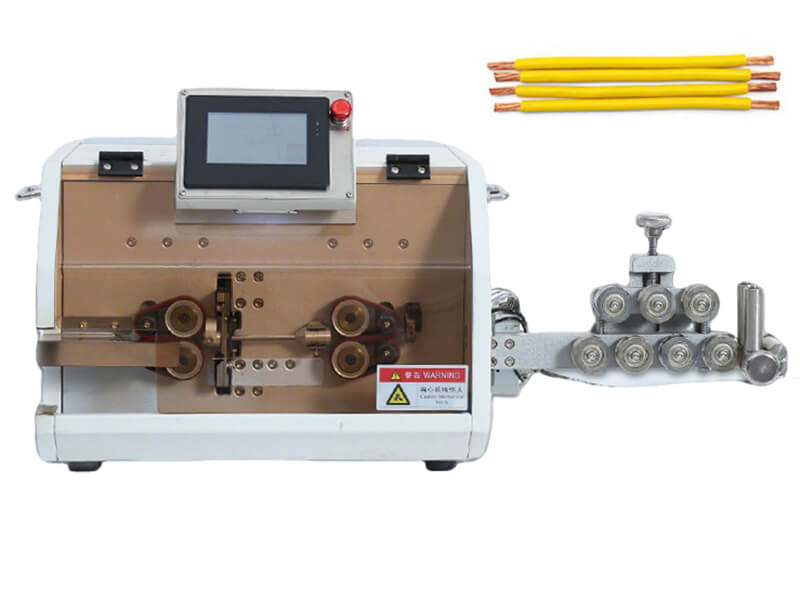

WS-930X is a functionally enhanced model in the WS-930 series, featuring an innovative composite blade holder design. It retains the proven and reliable traditional stripping system with upper and lower V-blades while additionally integrating a high-precision servo rotary blade holder.

WS-930X Wire Cutting and Rotary Stripping Machine

PRODUCT DESCRIPTION

The WS-930X is a functionally enhanced model in the WS-930 series, featuring an innovative composite blade holder design. It retains the proven and reliable traditional stripping system with upper and lower V-blades while additionally integrating a high-precision servo rotary blade holder. Users can flexibly choose or combine the two stripping methods based on the wire type and process requirements, enabling versatile and efficient processing of everything from standard cables to complex multi-jacketed cables.

FEATURES

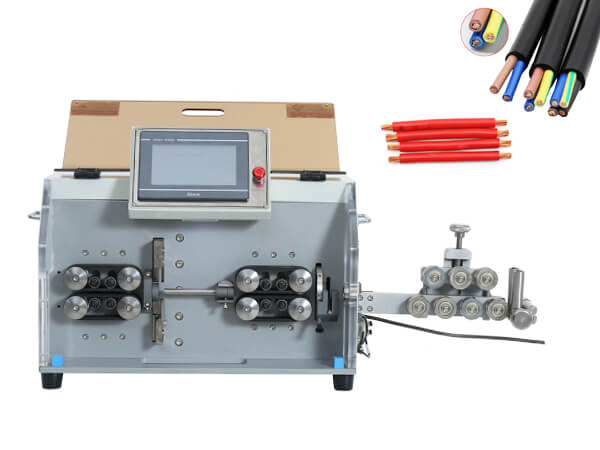

Dual Blade Holder Composite System: The core upgrade is the addition of an independent servo rotary blade holder alongside the traditional V-blade system. The machine possesses dual stripping capabilities: the traditional method is efficient and reliable for most wires, while the rotary holder is dedicated to specialized needs, achieving multiple functions in one machine.

Rotary Precision Stripping: The newly added servo rotary blade holder allows the tool to rotate and cut into the wire jacket for precision turning-style processing. This method is particularly suitable for stripping multi-layer jackets, shielding, or tough outer sheaths, enabling clean, layer-by-layer removal of up to 6 layers of material without damaging the inner conductors.

Flexible Configuration, Wide Application: Users can select the optimal stripping solution for different wire types (e.g., standard PVC wire, multi-layer shielded cable, elastic sheathed cable). This flexibility allows the WS-930X to cover a broader range of industry applications, from electronic wiring harnesses to high-end data cables and automotive cables.

TECHNICAL SPECIFICATIONS

Model | WS-930X |

Core Function | Rotary stripping, up to 6 layers |

Display | 7-inch True-color Touchscreen |

Stripping Range | 1 – 30 mm² |

Max. Wire Diameter | Φ18 mm |

Cutting Length | 10mm - 99999.99mm |

Length Tolerance | ≤ 0.002 × L (L = Cutting Length) |

Stripping Length | Front Full-strip: 1-190mm; Front Semi-strip: 1-1500mm Rear Full-strip: 1-80mm; Rear Semi-strip: 1-500mm |

Blade Material | High-quality High-Speed Steel |

Drive Method | 16-wheel Drive (Stepper Feeder, Servo Cutter) |

Feeding Method | Belt feeding, no indentations or scratches |

Productivity | 500-1000 PCS/Hour (depending on length and wire size) |

Power Supply | AC 220V 50/60Hz |

Air Supply | 0.5-0.7Mpa |

Rotary Blade Feed Method | Precision ground ball screw |

Number of Rotary Blades | 2 PCS |

Rotary Blade Drive | Feeding: Servo, Rotary Stripping: Servo |

Rotary Stripping Auxiliary Clamp | Servo + Precision ground ball screw |