The WS-9120H is an advanced upgrade in the WS-9120 series, specifically engineered for processing multi-core sheathed cables. Retaining all the high-precision and high-efficiency features of the base model, this machine innovatively integrates two independent blade holder systems. It can sequentially complete outer jacket stripping, inner conductor stripping, and fixed-length cutting in one fully automated cycle

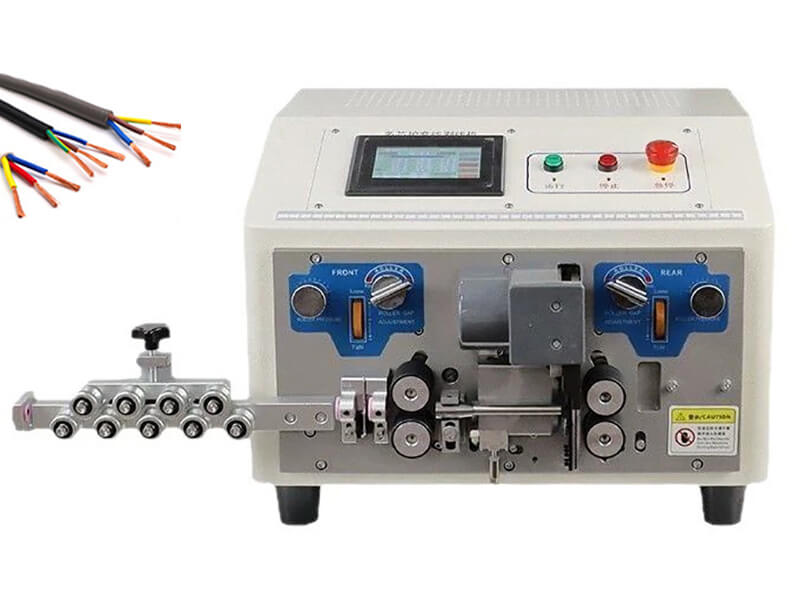

WS-9120H Automatic Wire Cutting Stripping Machine

PRODUCT DESCRIPTION

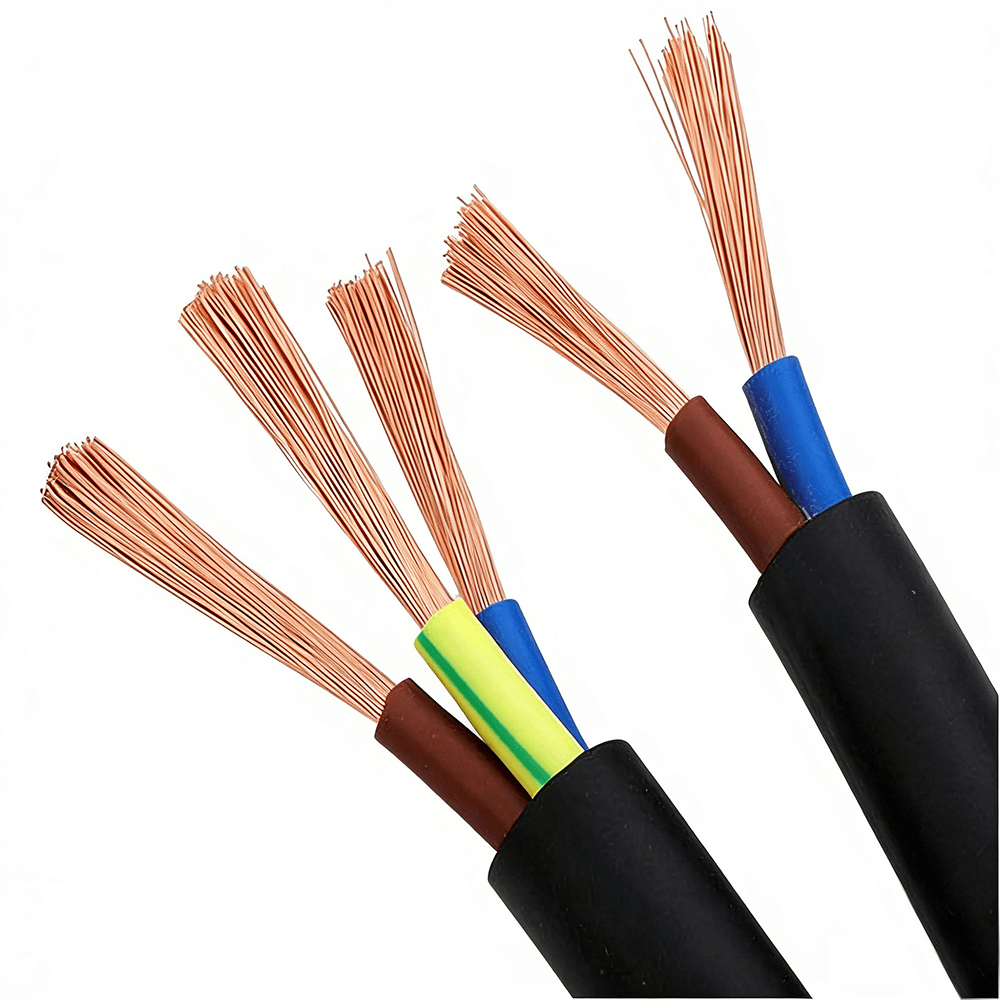

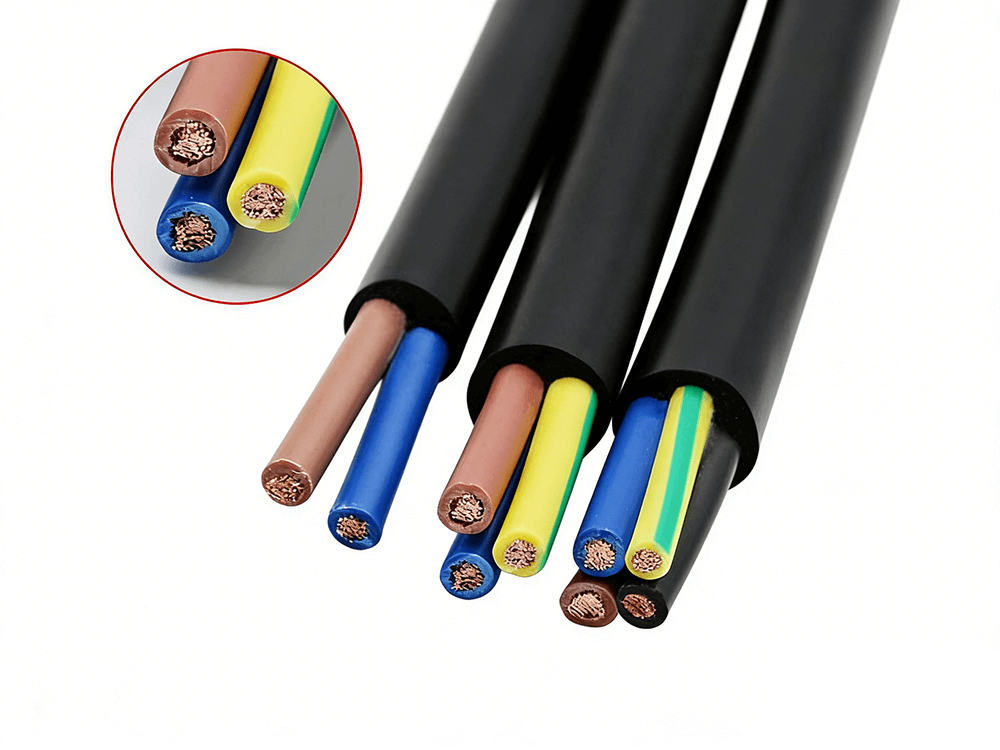

The WS-9120H is an advanced upgrade in the WS-9120 series, specifically engineered for processing multi-core sheathed cables. Retaining all the high-precision and high-efficiency features of the base model, this machine innovatively integrates two independent blade holder systems. It can sequentially complete outer jacket stripping, inner conductor stripping, and fixed-length cutting in one fully automated cycle, consolidating multiple processing steps for complex cables into a single operation. It is the ultimate solution for processing sheathed cables used in automotive wiring harnesses, industrial equipment cables, and more.

FEATURES

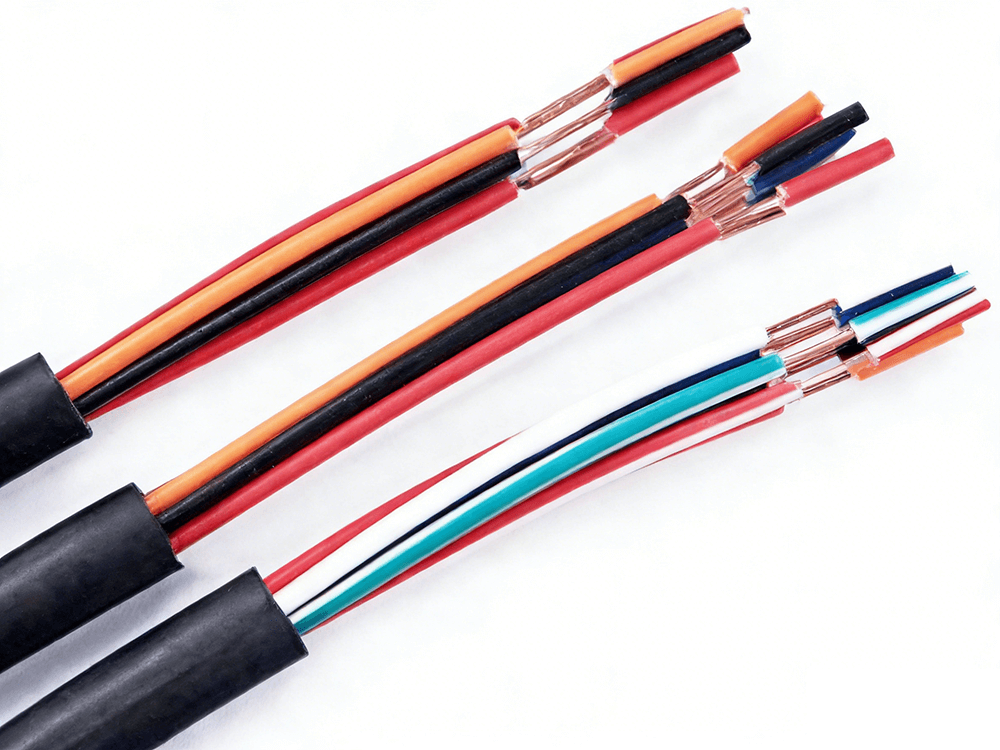

Dual-Blade Synergy, One-Step Completion: The core upgrade is the addition of a dedicated inner conductor blade, which works in tandem with the original jacket stripping blade. It automatically performs the entire process of "full strip of outer jacket → full/semi strip of inner conductors → precise fixed-length cutting" in one go, eliminating the need for secondary processing or machine changeover, thereby multiplying efficiency.

Precision Stripping, Non-Damaging Processing: Optimized for the structure of sheathed cables, both the outer jacket stripping length and the inner conductor stripping length can be set independently with precision. The 16-wheel belt feeding system ensures mark-free and scratch-free conveyance of the cable, especially the delicate inner conductors.

Inherited Performance, Proven Reliability: 7-inch true-color touchscreen control, cutting tolerance within ±0.002×L, wire handling capacity of 10-120 mm², and high-quality imported high-speed steel blades, ensuring long-term operational stability and processing consistency.

Intelligent & Efficient, Highly Adaptable: Programmable control allows switching between different sheathed cable specifications simply by recalling the corresponding recipe. It can quickly adapt to high-mix, batch production demands.

TECHNICAL SPECIFICATIONS

Model | WS-9120H |

Core Function | 1. Fully automatic cutting and stripping of wires. 2. For sheathed cable: Outer jacket stripping, inner conductor stripping, and cutting completed in one cycle. |

Display | 7-inch True-color Touchscreen |

Stripping Range | 10 - 120 mm² (Sheathed cable with up to 5 cores) |

Max. Wire Diameter | Φ25 mm (Guide Tube Size: φ25/20/15/10mm) |

Cutting Length | 1mm - 99999.99mm |

Length Tolerance | ≤ 0.002 × L (L = Cutting Length) |

Stripping Length | Front Strip: Outer jacket full-strip 30-200mm; Inner conductor strip 1-30mm Rear Strip: Outer jacket full-strip 30-150mm; Inner conductor strip 1-30mm |

Blade Material | High-quality High-Speed Steel |

Drive Method | 24-roller Drive (Stepper Feeder, Servo Cutter) |

Feeding Method | Belt feeding, no indentations or scratches |

Productivity | 800-1000 PCS/Hour (depending on length and wire size) |

Roller Lifting Method | Stepper Motor Lifting |

Guide Tube Swinging | Pneumatic Cylinder |

Power Supply | AC 220V 50/60Hz 1.5KW |

Air Supply | 0.5-0.7Mpa |

Weight | 280kg |