The AC-330P is a high-end, professional-grade machine built upon the proven AC-330 series, featuring significant functional enhancements. It retains the core advantages of fully automatic PLC control and precise fixed-length cutting while innovatively integrating a built-in slitting function.

AC-330P Automatic Tube Cutting Machine

PRODUCT DESCRIPTION

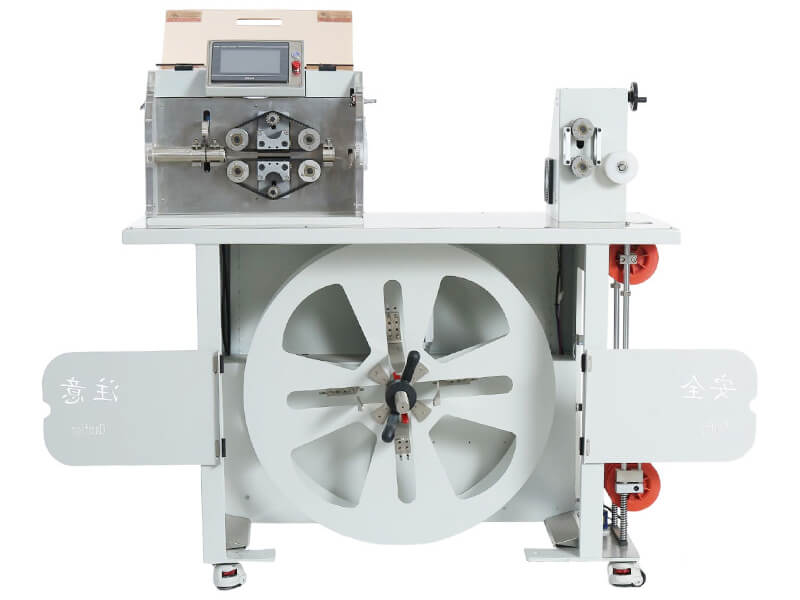

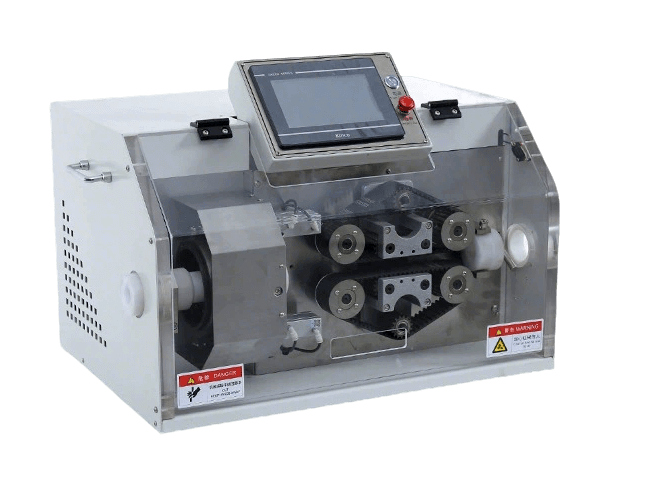

The AC-330P is a high-end, professional-grade machine built upon the proven AC-330 series, featuring significant functional enhancements. It retains the core advantages of fully automatic PLC control and precise fixed-length cutting while innovatively integrating a built-in slitting function. This enables the complete automation of both cutting and slitting corrugated tubes in a single cycle. With its power substantially increased to 700W, it is specifically engineered for high-intensity production environments demanding superior efficiency and integrated multi-functionality.

FEATURES

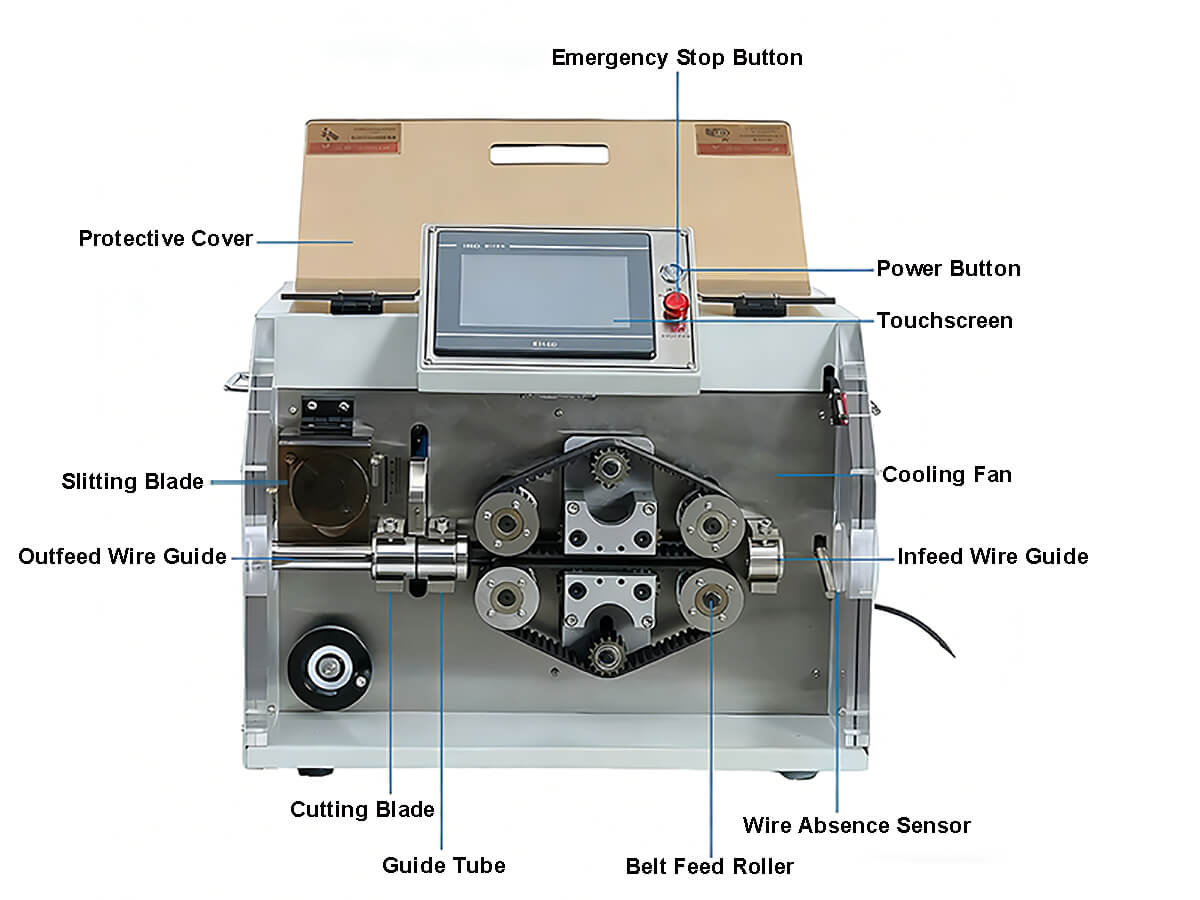

1. Exclusive Integrated Slitting Function: The standout feature of this model is its ability to perform a precise longitudinal slit along the tube axis immediately after the fixed-length cut, using a built-in precision slitting blade. It completes two processes in one machine, dramatically improving processing efficiency for applications like wire harness protection or cable installation, eliminating the need for secondary manual slitting operations.

2. Comprehensive Power Upgrade: The motor power has been increased from 300W to 700W, delivering more robust and stable cutting force. This enhances performance for continuous, high-density cutting tasks and is particularly effective for larger diameters or thicker-walled tubes requiring simultaneous slitting.

3. Robust and Stable Construction: To accommodate the enhanced power and new functionality, the frame has been reinforced. The weight is now 75KG, ensuring overall rigidity and stability during high-speed operation and the slitting action. This minimizes vibration and guarantees consistent processing accuracy.

4. Unchanged Intelligent Control: It maintains the intelligent PLC and Touchscreen HMI control system. All new parameters (e.g., slitting depth, mode) can be set and adjusted intuitively on the screen, ensuring equally simple operation.

SUITABLE MATERIALS

Ideal for sectors such as automotive wire harnesses, electromechanical equipment, and construction engineering, where the processing workflow requires corrugated tubes to be both cut to length and slit open for sleeving over cables or wire bundles. It is a professional solution for boosting pipeline assembly efficiency and enabling automated batch production.

TECHNICAL SPECIFICATIONS

Model | AC-330P |

Core Function | Fixed-Length Cutting + Longitudinal Slitting |

Control System | PLC + Touchscreen HMI |

Cutting Method | Motor Direct-Drive Cutting |

Stroke | 30mm |

Power Supply | AC 220V 50/60Hz |

Power | 700W |

Cutting Diameter | ø5 - ø30mm (φ30 - φ45mm customizable) |

Length Tolerance | ±0.5% |

Cutting Speed | 10 - 60 pcs/min (depending on length) |

Dimensions | L580*W470*H500mm |

Weight | 75kg |